Hub-Tite™ Spindle Solutions

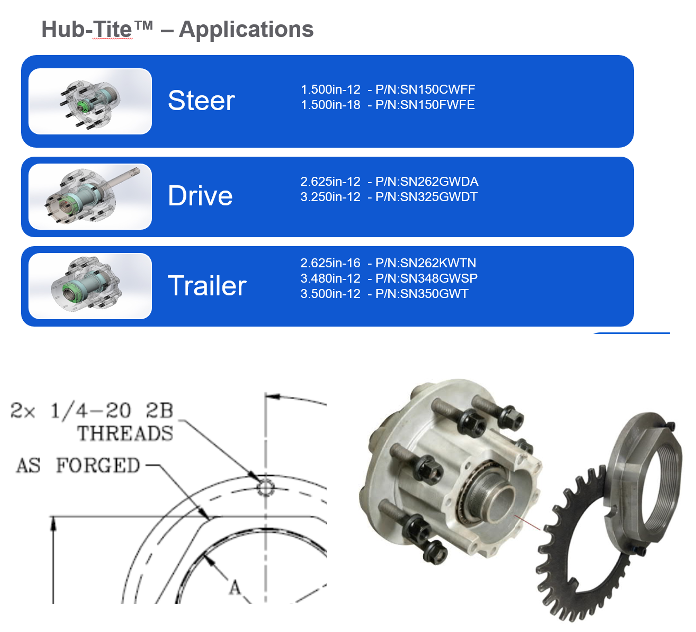

Hub-Tite™ wheel bearing lock-nut system provides a simple, robust and affordable lock nut system for light, medium, and heavy-duty applications, including: Steer/Drive/Trailer.

Hub-Tite™ is easy to install and can be used to address most after market and OEM spindle configurations. Please view the Hub-Tite™ Installation Instructions. For your convenience please print double sided to produce a pocket pamphlet.

Simplicity is key. Safety cannot be compromised. Please see the above installation video.

Simple adjustment procedures assures proper end play for maximum seal and bearing life. Positive locking system by 2 cap screws ensures a redundant factor of safety.

Okabe is confident Hub-Tite™ will exceed your expectations whether it be OEM or aftermarket. A 7-Year limited warranty is offered.

Download the Hub-Tite™ Brochure.

Features

- Easy, quick, ergonomically friendly installation DOES NOT require special tools. Please view the Hub-Tite™ Installation Instructions.

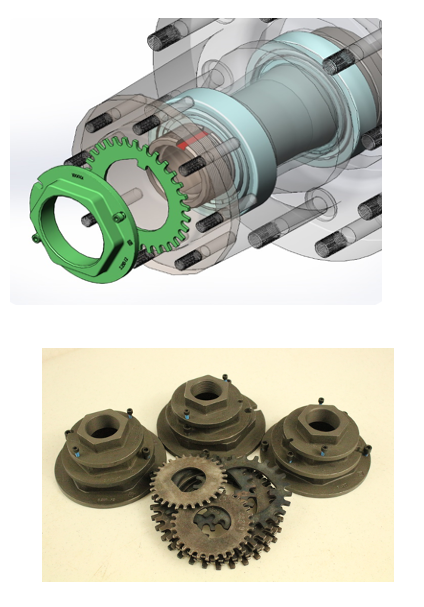

- Precision stamped, tempered and quenched washer with unique notches designed to ensure the nut is positively locked to the spindle.

- Hot Forged nut is stronger and more durable than sintered heat-treated nuts.

- The most thread engagement of any spindle nut for maximum connection of the nut and spindle.

- The nut is easily locked onto the spindle in proper position through engagement of the nut and washer using Grade 8 Socket Head Cap screws with nylon patch. Cap screws are located 180 degrees equally distant to distribute and balance the forces on the nut.

- The unique washer design allows for less than 0.0028 inch of "back off" per notch to maintain proper control of the end play adjustment to meet specified bearing pre-load requirements which minimize heat and wear, extending the bearing life in the hub.

Benefits

- Simple two-piece system without snap rings

- No special installation tools required

- Universal design for Drive, Steer and Trailer Hubs